Total: RM0.00

Buteline HDPE Fitting for Cold Water Series Tee

HDPE Fitting Equal Tee

- Specifications for Buteline HDPE Fitting for Cold Water Series Tee

Additional information

| Model | TE |

| Color | Black |

| Material | HDPE |

| Standard | ISO 14236, MS 1058, AS/NZS 2642, 4129/4130 |

- Description for Buteline HDPE Fitting for Cold Water Series Tee

Buteline HDPE fittings are integrally strong and durable, moulded from thermoplastic and pre-fitted with annealed aluminium sleeves. These maintenance-free plumbing fittings, once clamped with it's Counterpart HDPE pipe will form a unique and technically superior joint. Users will find the total concept much quicker and more economical than other available systems.

Designed using hydraulic engineering concepts proven on high pressure hydraulic fitting-to-hose connections, Buteline fittings have an outstanding feature which enable them to overcome high stresses experienced in installation and while in service. The aluminium rings transfer all loads applied on the tail section to the strongest section of the fittings, thereby eliminating the risk of failure. Buteline fittings are technically superior, giving superb performance and durability over the long term with over 50 years of service life.

Buteline Hot & Cold Water Piping System

The Buteline Plumbing System is designed for Hot & Cold water reticulation using Polybutene-1 (PB-1) pipe, or for Cold water only using Polyethylene (PE 80) Pipe, Buteline always represents quality and only select materials which are specifically designed for their application. Both PB-1 and PE System utilise Buteline's proven and efficient clamping technique, and offer all the Buteline benefits with their respective cost advantages.

The Buteline Plumbing System is manufactured to conform to many international standards and approvals, but specifically complies with the following :-

- SPAN Approvals (Suruhanjaya Perkhidmatan Air Negara)

- ISO Standard ISO 14236

- Malaysian Standard MS1058 (PE Pipe)

- Australia/New Zealand Joint Standard AS/NZS 2642

- Australia/New Zealand Joint Standard AS/NZS 4129/4130

- Watermark AS/NZ 2642

- United Kingdom British Standard BS 7291

Main advantages & Features of Buteline PE & PB Fittings

- Lightweight, slim-line, one-piece design (no O rings or inserts) which is easy to use and not bulky

- Post-clamp flare provids visual indication of joint completion

- Able to provide metal-free contact with water supply, better hygiene, no leaching of harmful substances

- Corrosion resistant, no scale build-up

- Use is not geographically restricted by geothermal conditions or hard water regions

- Easier to install, no time-wasting with bulky tools, sliding sleeves, or searching around for lost copper rings.

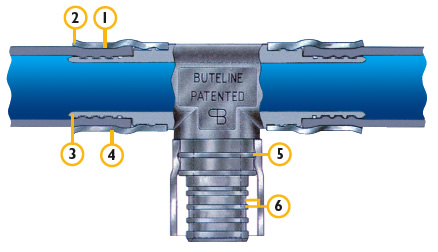

Buteline Jointing System

- 8mm WIDE FORGED CLAMP - Minimum working stress applied (approx. 0.5 ton per sq. in.) allowing pipe material to "flow" into insert tail grooves.

- 2mm WIDE FLARE - No stress from clamping transmitted to insert tail or pipe at end of fitting. End of metal sleeve cannot impinge into pipe, even in bending.

- TAPERED ENTRY, SMOOTH BORE - Minimise resistance to water flow.

- METAL REINFORCING SLEEVE - Guarantees no stress break in this critical area.

- FULL LENGTH ALUMINIUM SUPPORT - Provides additional rigidity and resistance to pull-off. Seals against dirt and moisture.

- SEALING RIBS - Narrow lands with wide grooves, ensure clamp stress is transferred into the pipe joint efficiently.